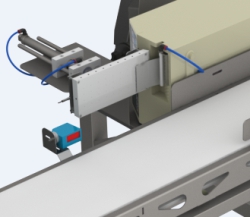

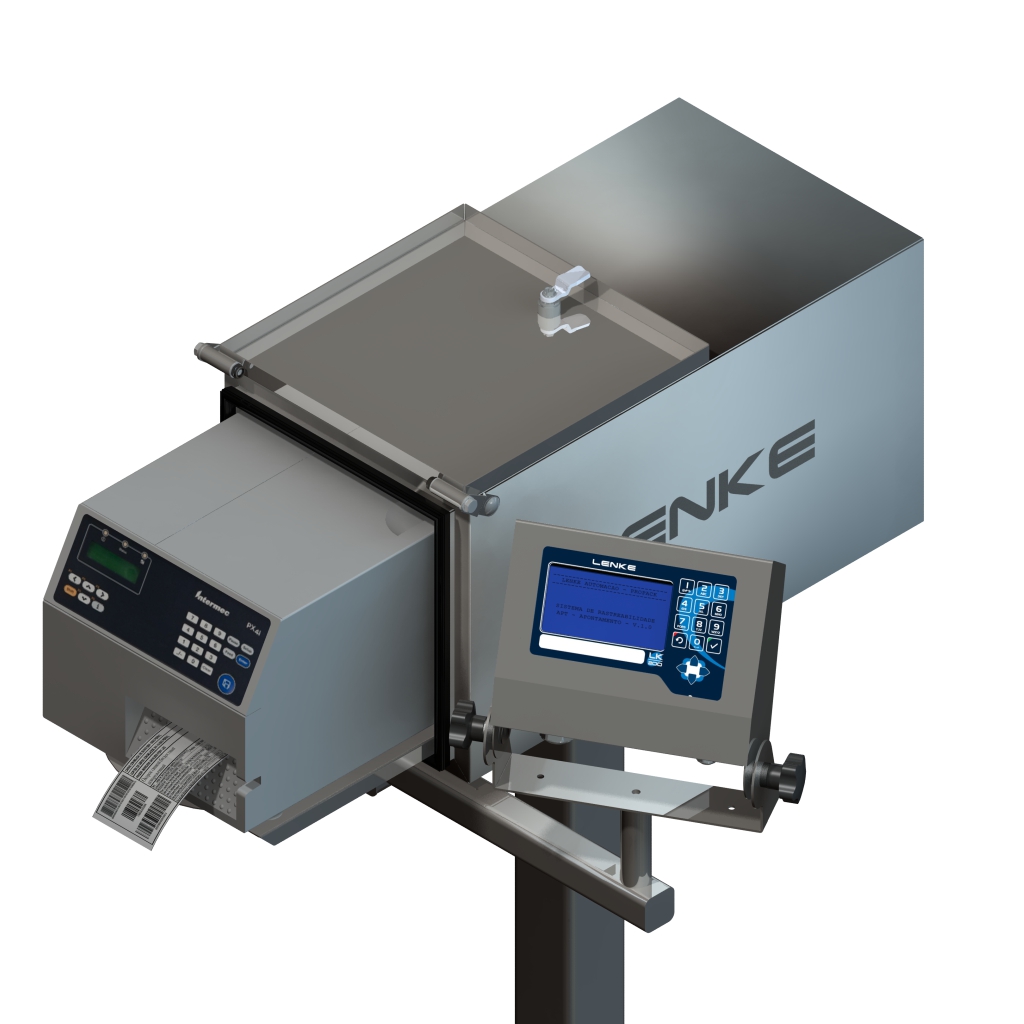

AP-300 Labeller

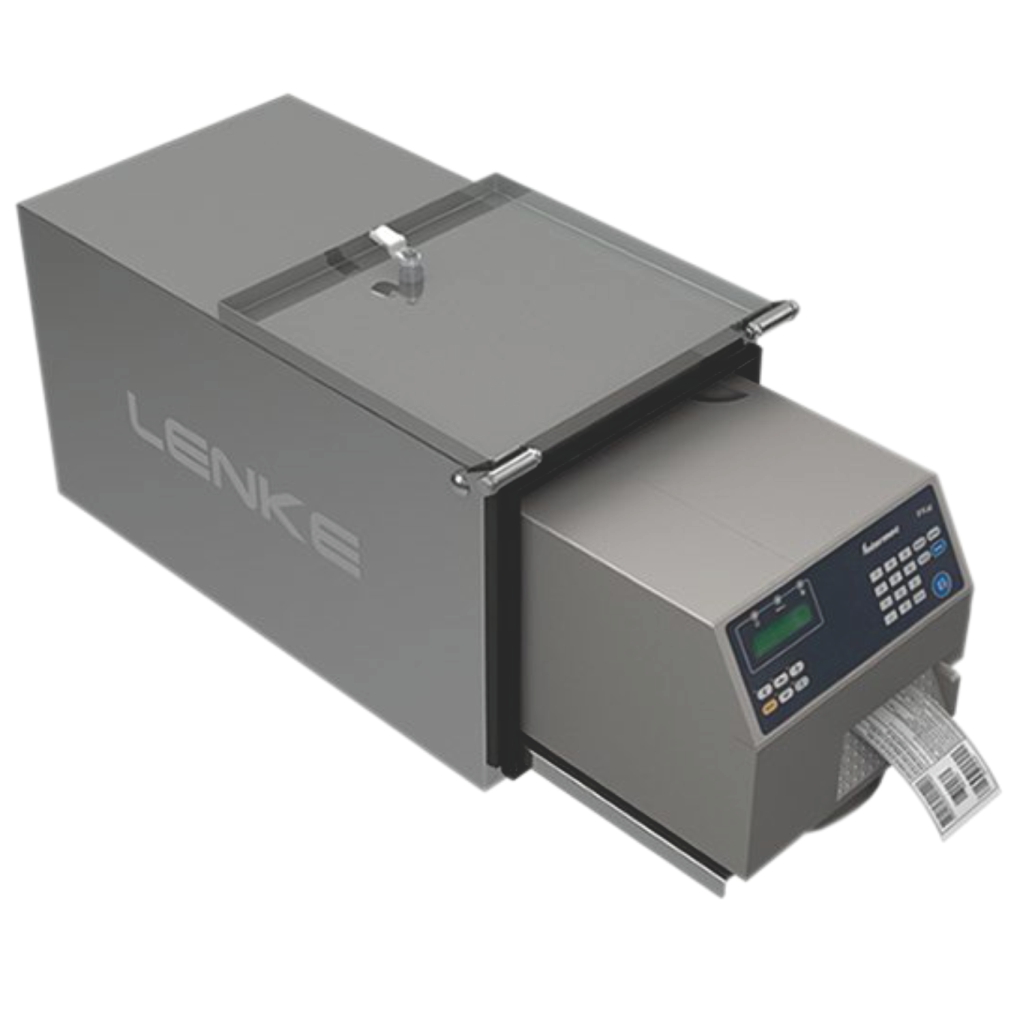

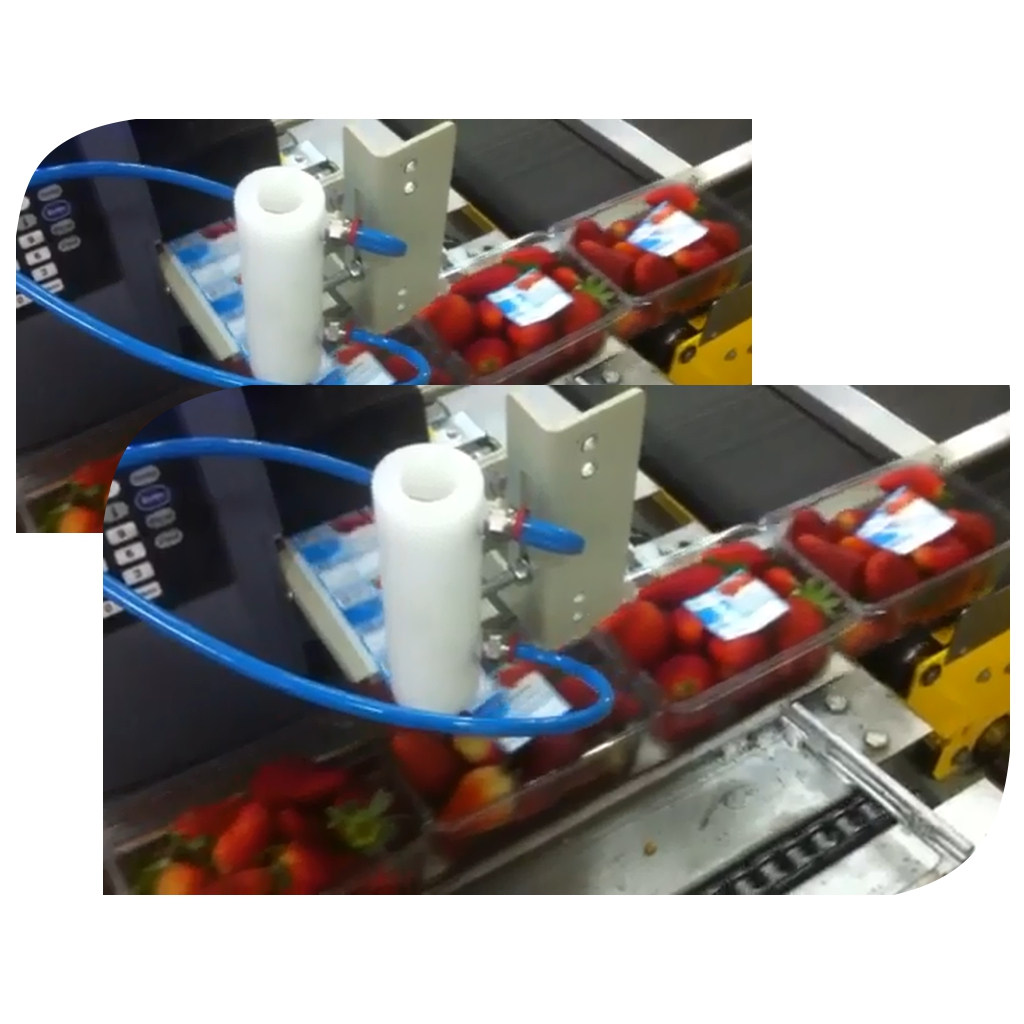

The printer label applicator Lenke AP- 300 was developed to enable efficient production workflow with automation of the labeling process. The machine is controlled by industrial micro LK-200 and can generate many different labels on the same production line. In line with multiple products, a scanner records the product information by reading the barcode and generates the final label may contain weight, type of product, traceability code, and expiration date.

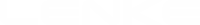

This information can be used to make appointment inventory and generation of pallet. For lines with multiple products you can use the code information to separate the product into different channels according to the final destination. Printer used is Intermec PM4i brand, known for robustness and versatility of the application and is designed to minimize maintenance. The application can either be blown with bristles or pneumatic piston contact. Labels can be of varying sizes, minimum 35mm x 35mm and 102mm x 250mm maximum.