Description

|

VERSIONS

|

| SOLUTIONS | TECHNICAL CHARACTERISTICS |

|

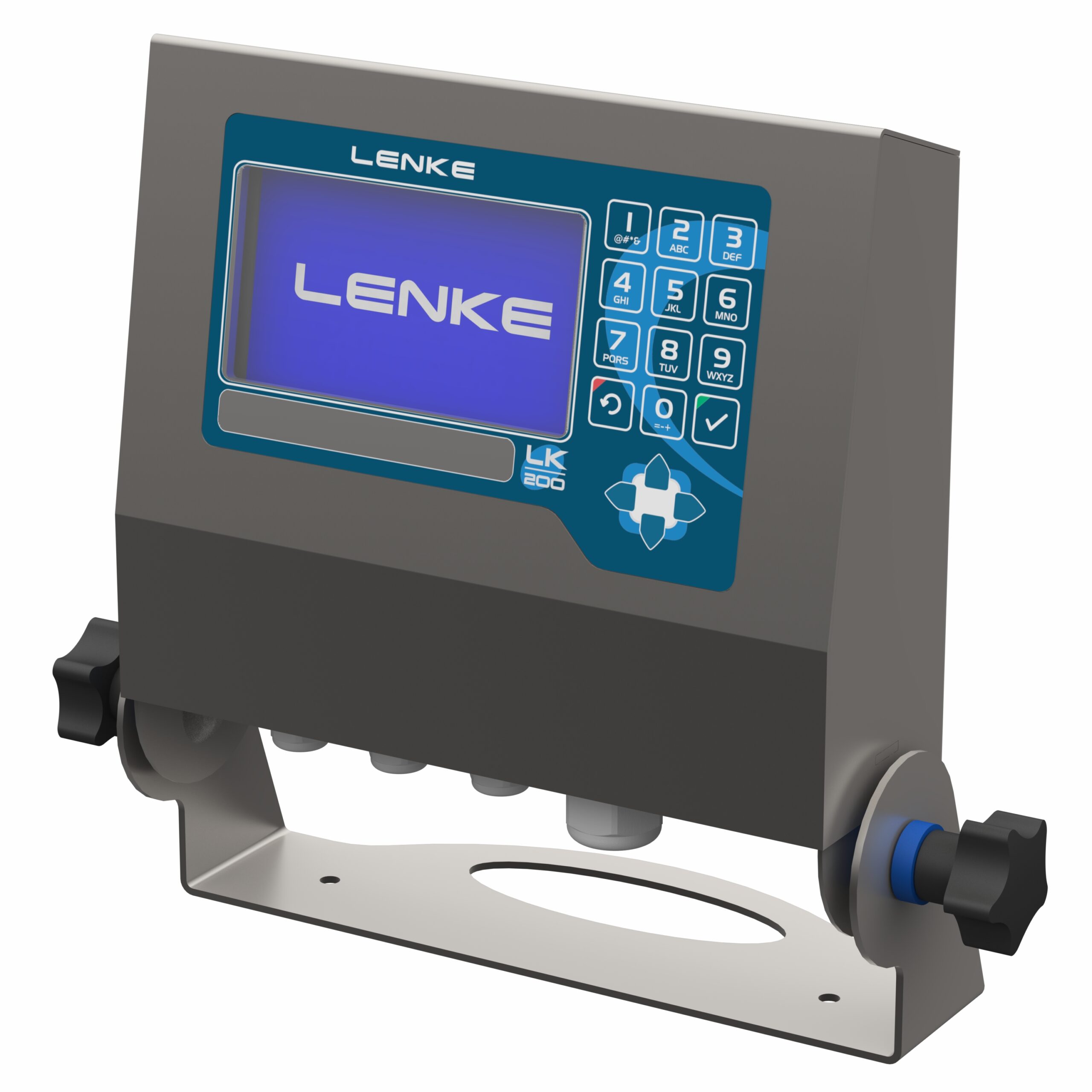

Constructed of stainless steel and incorporating the best components available on the market, the Lenke LK 200 terminal meets the most strict requirements of the food industry. The overload protection against side and vertical impacts ensures a long service life of the industrial terminal.

|

The LK200 terminal has the following human-machine communication and interaction interfaces:

Ethernet 1x IEEE 802.3,10/100 BASE-T

3 RS232 serial ports

4 digital inputs

8 digital outputs

Graphic LCD display

Keyboard with 16 keys

|

| RELIABILITY |

|

The LK2500 has an extremely fast response time and can work in places where there is shake without losing stability. Therefore, it is an ideal option for applications that demand high speed and productivity.

|

| HARDWARE |

|

Our terminal features a high-performance, low-power RISC architecture processor:

2MB RAM

ROM Memory 128kB

ARM7 processor

72MHz Operating Frequency

63 million instructions per second

|