Description

| SOFTWARE | ROBUSTNESS |

|

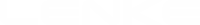

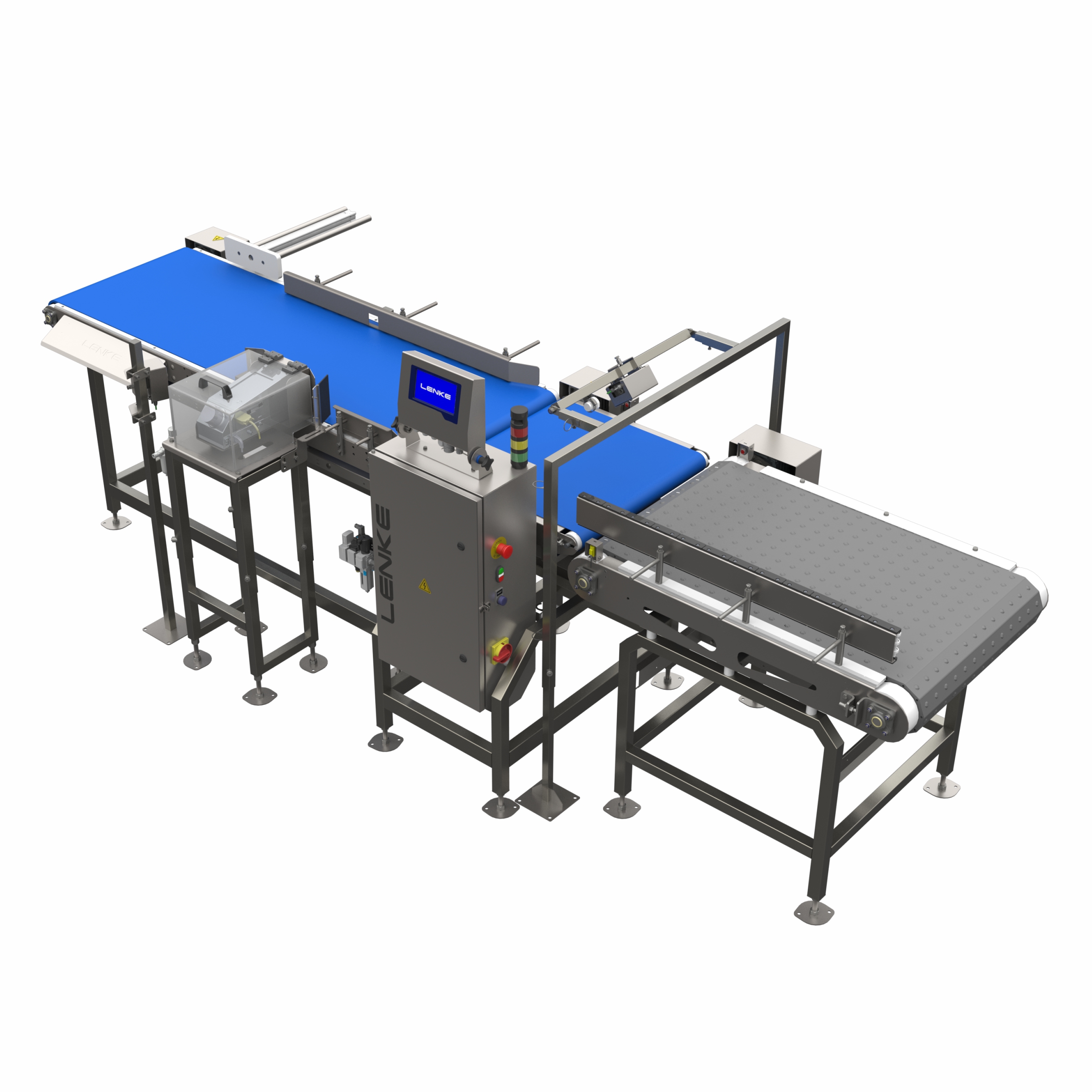

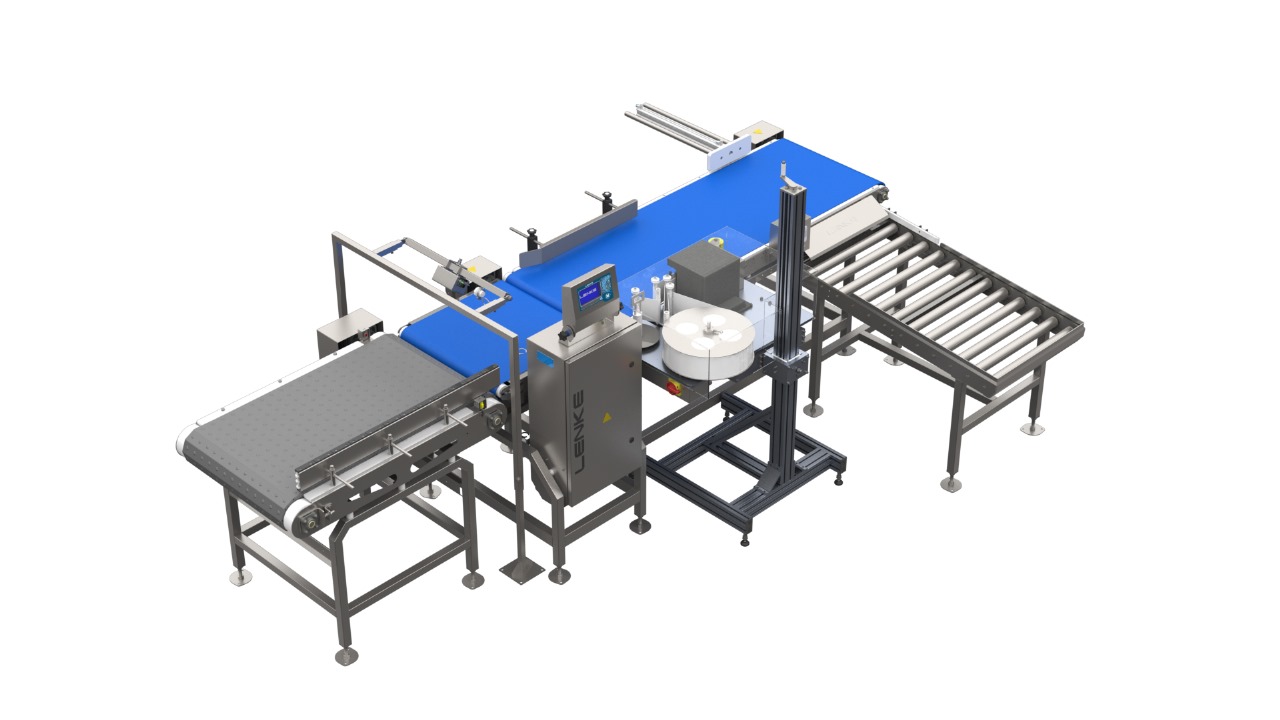

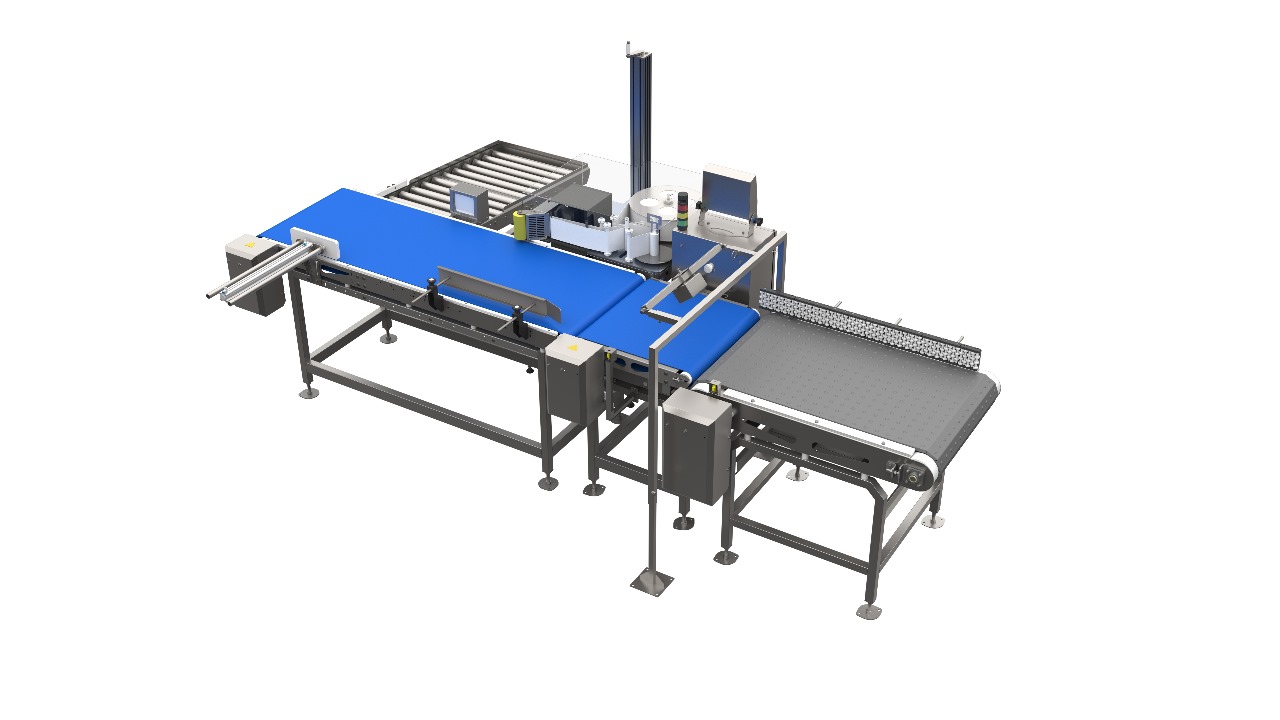

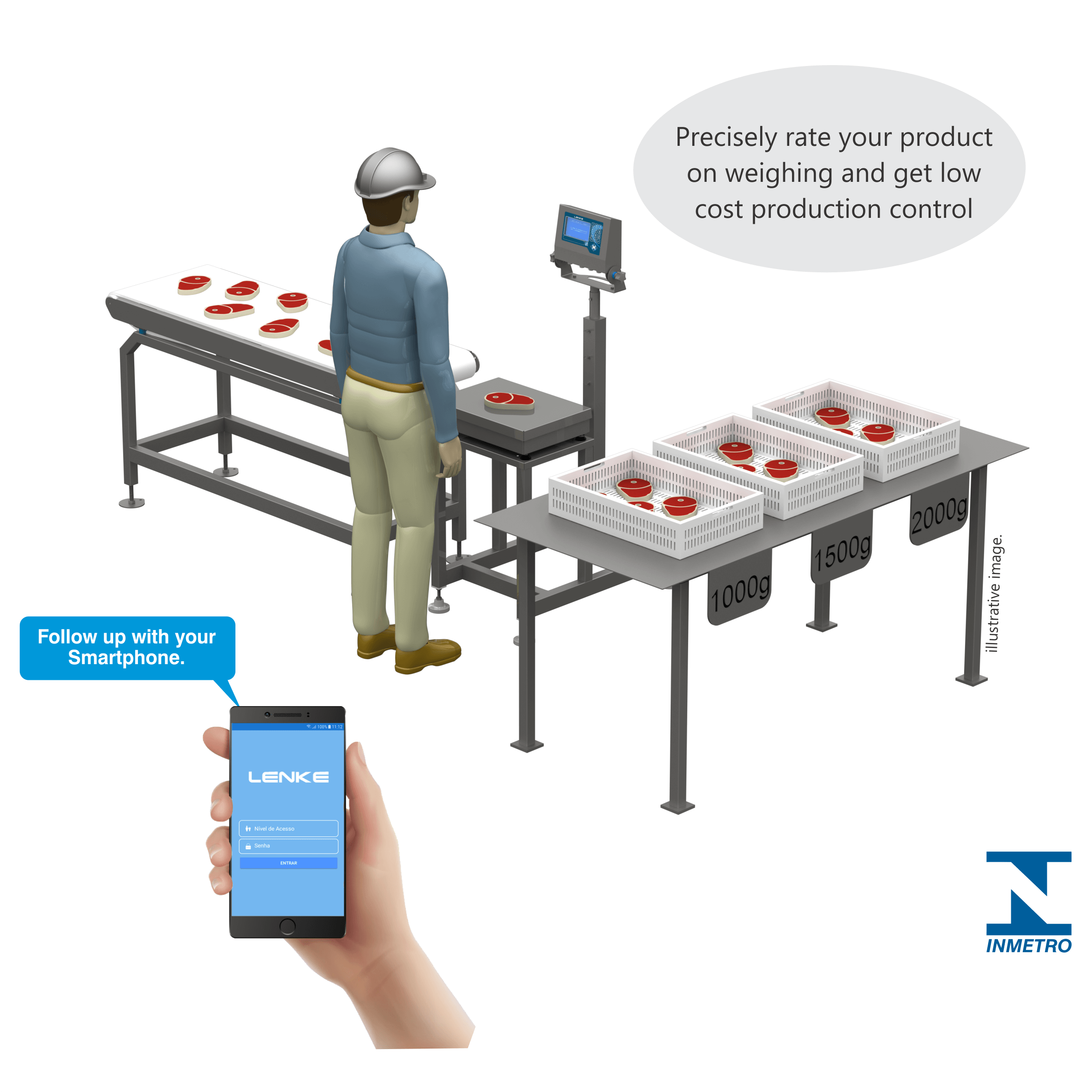

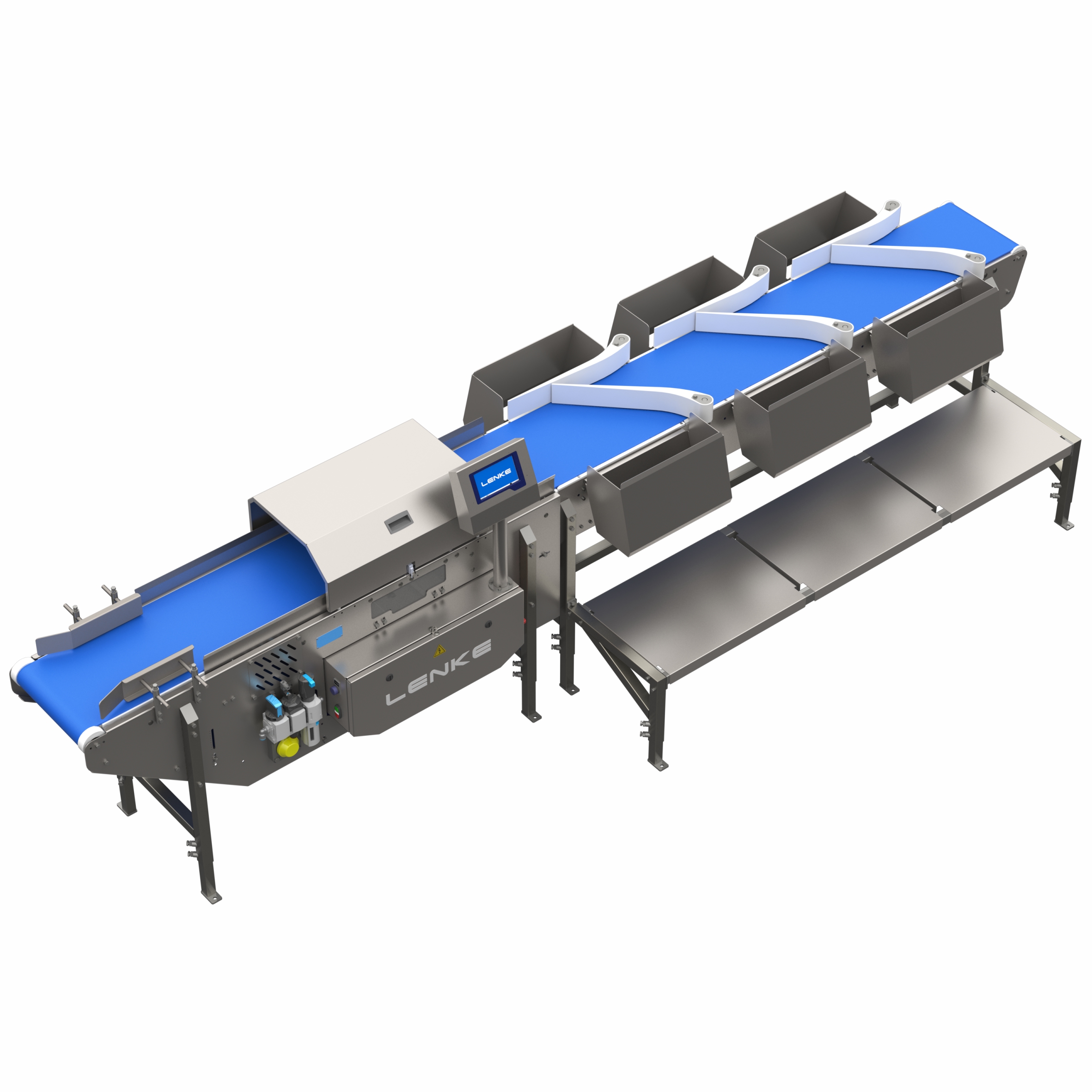

The Lenke VP-1215 software has several features in the standard version and allows customization according to the customer’s needs. Production data is exported to the customer’s database and allows a clear view of what was produced during a given period.

|

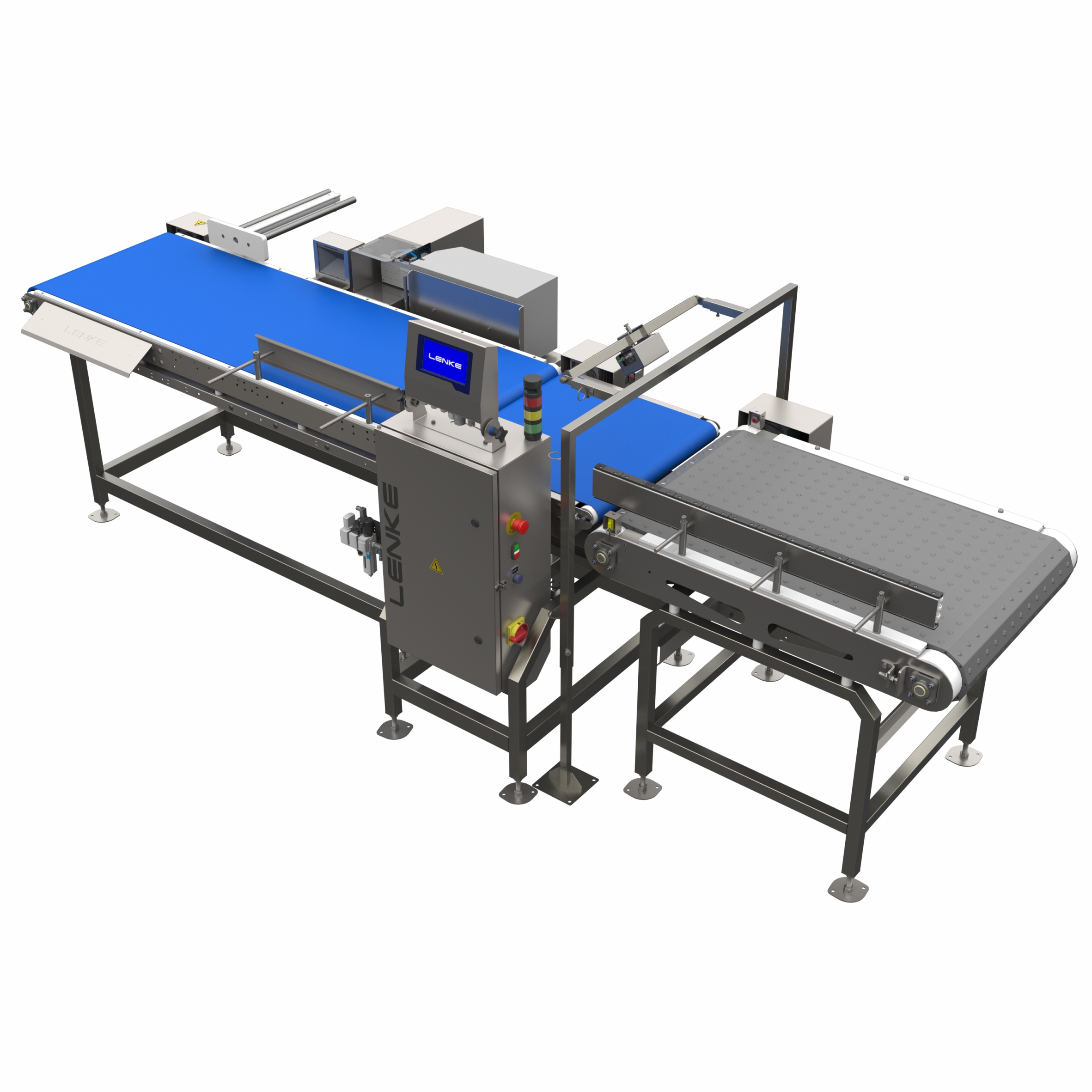

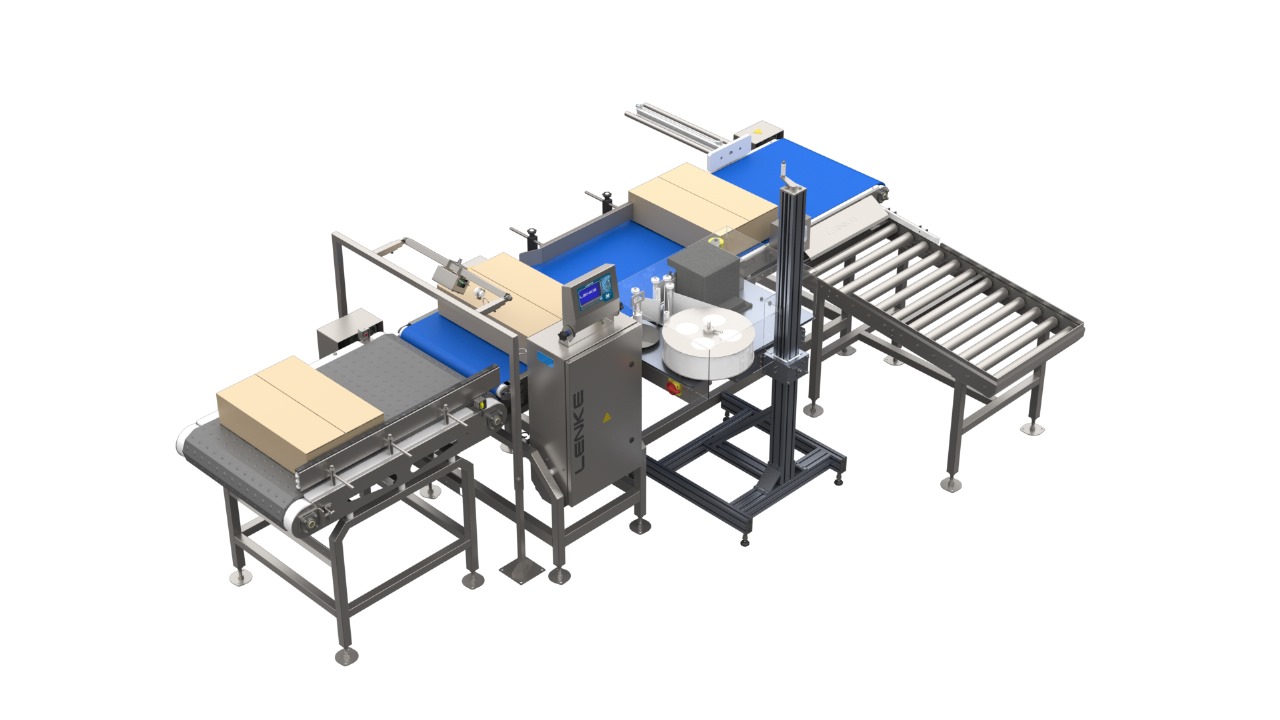

Lenke VP-1215 is made out of the best available components and each part of the machine was designed considering continuous usage, in 2 or even 3 daily shifts. The equipment is made of stainless steel and non-corrosive materials. The machine perfectly supports cleaning procedures of the food industry. |

| MAINTENANCE | TECHNICAL SUPPORT |

|

Maintenance of the equipment is simple and the design is compact, reducing components to the minimum required.

|

LENKE has been operating in the market for more than 20 years and has an experienced team of professionals to serve your company with quality and efficiency.

|