Description

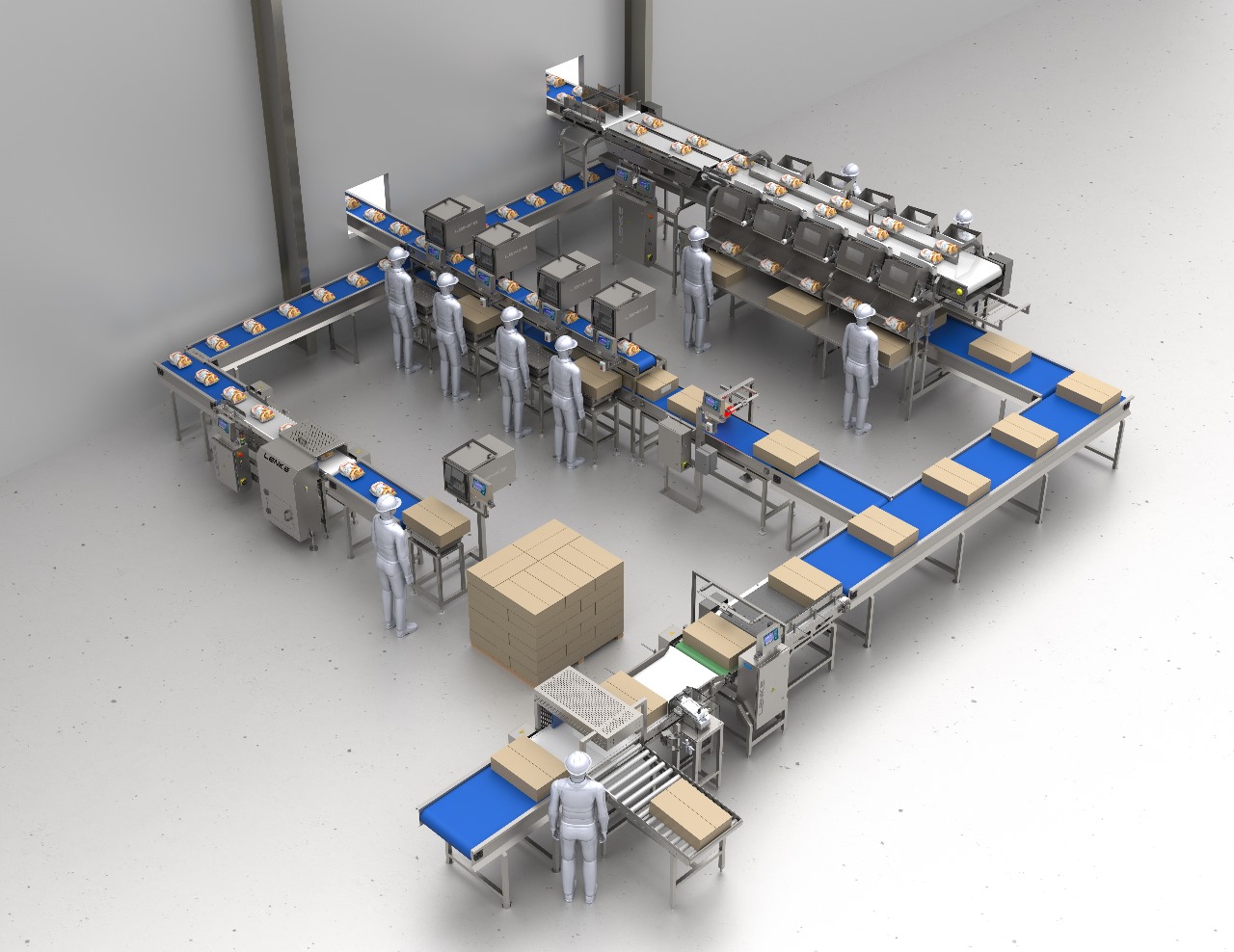

| Robustness | Technical Features |

| All the machine’s conception took into account adverse working conditions, in two or three daily shifts and intensive cleaning with water jets. The components used were carefully chosen in order to allow long durability. The equipment is made of stainless steel and polymers approved by the food industry. The indicator LK200 has IP67 armoring which avoids moisture permeation. | The machine body is made of stainless steel, assuring strength and durability.

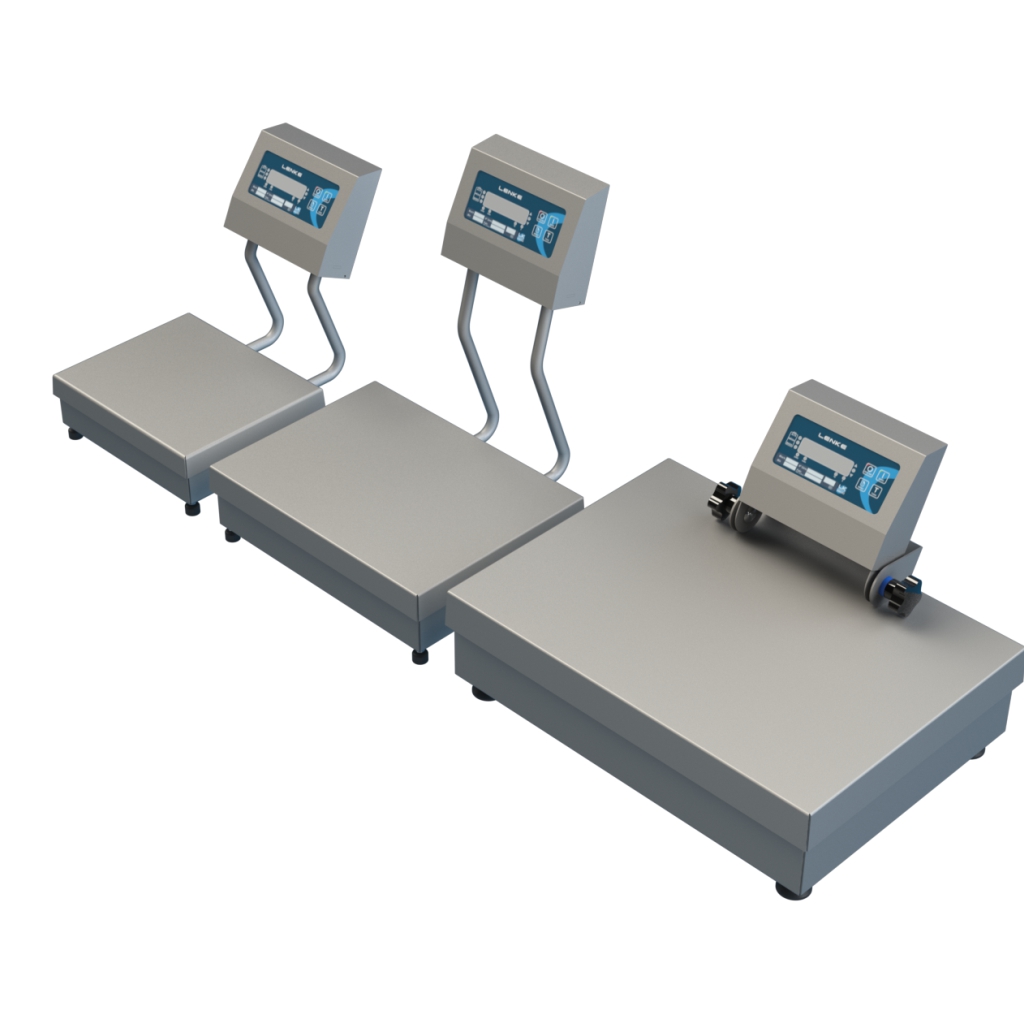

CL3500 has Ethernet communication, two RS232 bidirectional serial and a USB 2.0 door. Power supply is 3×380 + N, and consumption of 0,75 kW. |

| Productivity | Connectivity |

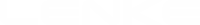

| The production capacity of Lenke graders is 160 portions per minute for the single machine and 320 portions per minute for the double machine. In order to achieve the maximum performance of the machines, Lenke offers a broad variety of conveyor belts which can suit the layout and the products to be graded. For a better productivity Lenke has developed the double flow grader which can classify double the number of portions, still using nearly the same space as a single flow machine. | The indicator LK200 may be connected through Ethernet with the client’s computers, providing valuable production data. |