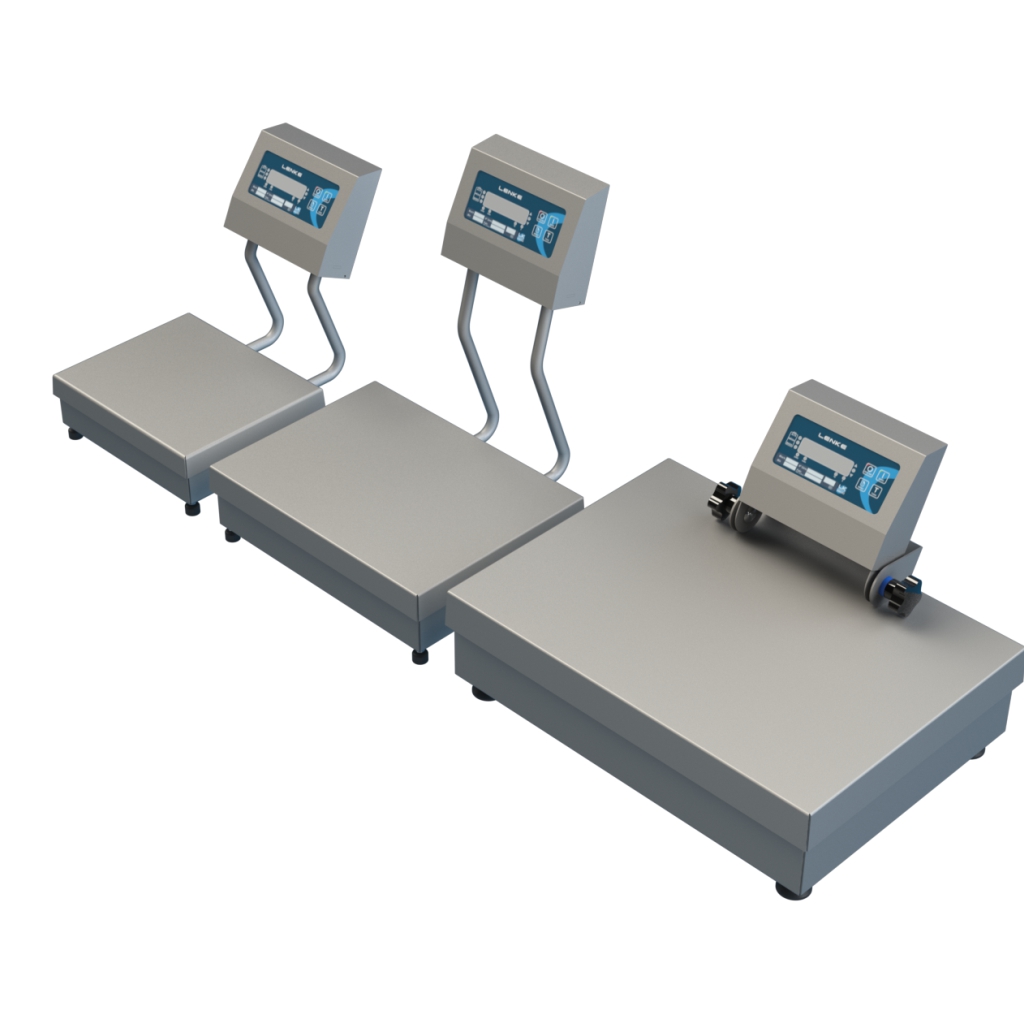

Description

| SPACE OPTIMIZATION |

|

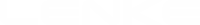

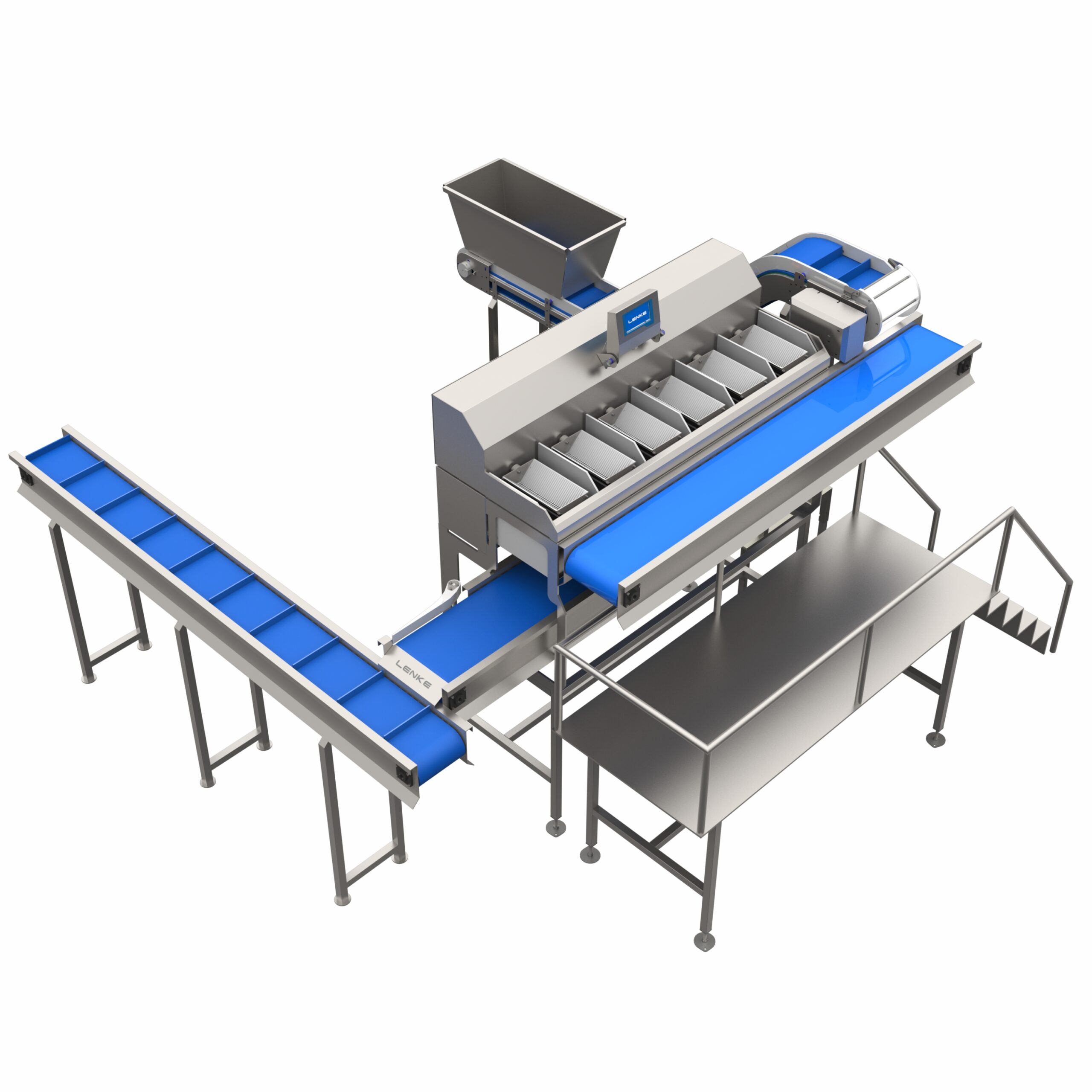

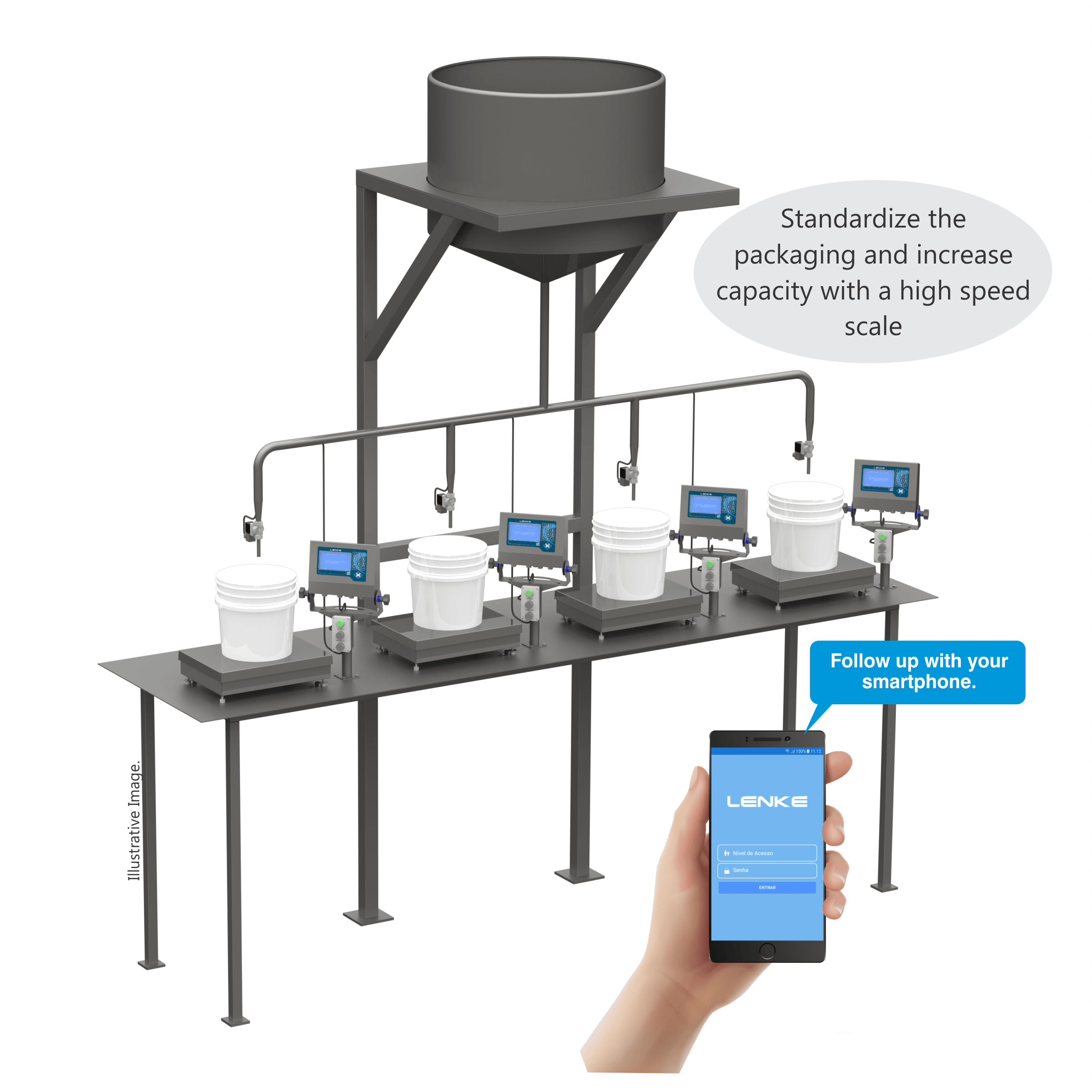

The MC-3500 is designed for accurate and efficient batching. With a flexible configuration, it allows customers to determine the number of trays/scales that best meet their needs according to their desired productivity. The MC-3500 can also be equipped with a dispensing belt, where the formed batches are properly distributed to the operators so that they can pack them, it is also possible to integrate/synchronize with automatic packaging machines.

|

| ROBUSTNESS |

|

The MC-3500 is built to withsatand the harshest operating conditions. Its robust structure, made of stainless steel and polymers approved by the food industry, ensures durability and reliability, even in high-volume production environments and under intensive sanitation.

|

| PRODUCTIVITY |

|

The MC-3500 stands out for its production capacity in a compact size. With it, you can speed up production, eliminate the need for manual weighing, and adapt to different products and production layouts, with greater data accuracy and reliability.

|

| CONNECTIVITY |

|

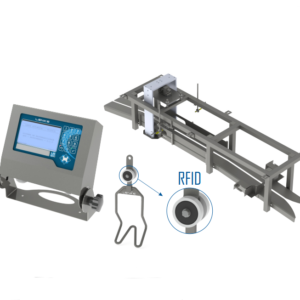

Equipped with advanced connectivity features, the MC-3500 includes Ethernet and Wi-Fi communication. This allows easy access and remote monitoring of machine information through web browsers, as well as enabling integration with databases. These features provide an optimized workflow and more efficient production management.

|